The effective sealing of pumps and valves depends on the overall condition of each component. Make sure that the equipment that needs to replace the packing has been effectively isolated according to the site and system. Correctly installing the packing is also the key to ensuring the sealing effect.

Preparation before installation of sealing packing

Removal of old packing Inspection of the stuffing box is a critical part of pre-installation preparation.

Before adding packing, take out all the old packing with special tools, and wipe the stuffing box clean.

Observe whether there are defects such as damage and eccentricity in each part of the stuffing box. Damaged valve stems, shaft sleeves and stuffing boxes can affect the performance of the packing.

Check that other components are still applicable. Replace any broken parts.

Choose the right packing for the sealing packing

There are two things that must be considered when picking out packing. The requirements of the working conditions should be consistent with the performance of the packing. The packing that best meets the requirements can be selected according to relevant technical data.

The packing size must be correctly selected according to the sealing requirements. In order to determine the cross-section, please use the following formula to calculate:

Cross section = (stuffing box diameter - stem diameter) / 2

Damaged installations may require packing with a slightly larger cross-section to compensate for the damage.

Installation of sealing packing

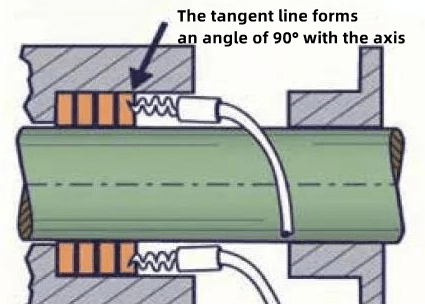

Carefully install each packing ring, wrapping each packing ring around the shaft or stem. Make sure this ring is fully seated in the stuffing box before installing the next packing ring. The next rings should be staggered and at least 90 degrees apart. After the last ring is installed, tighten the nut by hand, and press down the gland evenly. If there is a water seal ring, check whether the distance between it and the top of the stuffing box is accurate. Also make sure that the shaft or stem can turn freely.

Adjust the packing

1) Pump packing

(1) Continue to tighten the gland nut by hand;

(2) After turning on the pump, adjust the gland nut, and a little more leakage is allowed at this time;

(3) Slowly tighten the gland nut to gradually reduce the leakage until the leakage reaches an acceptable level;

(4) If the leakage stops suddenly, the gland nut should be screwed back and readjusted to prevent the packing from overheating;

(5) Just adjust the leakage rate to a stable state.

2) Packing for valves

Consult the packing manufacturer or the technical department of the company about the torque specification or compression percentage, and tighten the gland nut according to the following steps:

(1) Apply torque to the gland nut to 30% of full torque;

(2) Repeatedly open and close the valve several times, and apply full torque when the valve is in the closed position;

(3) Repeat step (2) 3 or 4 times.

After the valve is put into use under normal working conditions, the packing group should be tightened for the last time to reserve sufficient margin for future stress relaxation.

After several hours of operation, check the adjustment of the gland and tighten if necessary. When the gland cannot be adjusted any further, the packing must be replaced.

Top-Sealing since1979, specializes in producing high quality Packing, including: Aramid Gland Packing、PTFE Gland Packing、Graphite Gland Packing、Carbon Gland Packing、Ramie Gland Packing、PTFE Gaskets, Graphite Gasket, Graphite Ring,Graphite Paper, Graphite Sheet, Graphite Tape, PTFE Sheet, Fiberglass Cloth, Fiberglass Tape, Fiberglass Rope, Ceramic Fiber Cloth, Ceramic Fiber Tape,Ceramic Fiber Rope

For more products, please visit it www.sealings.cn

Welcome to mail:[email protected] or call 0574-62837600