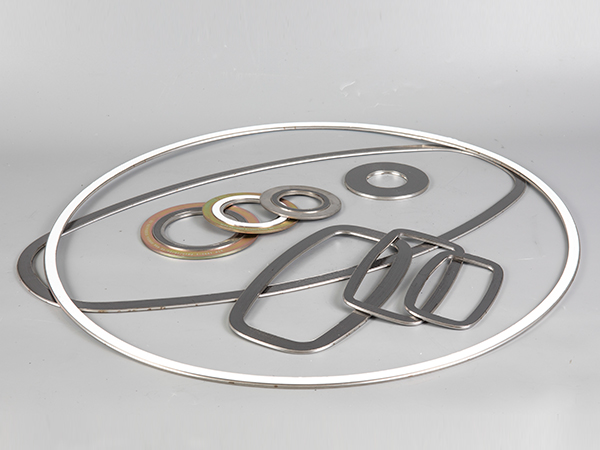

Non-Metallic Gasket

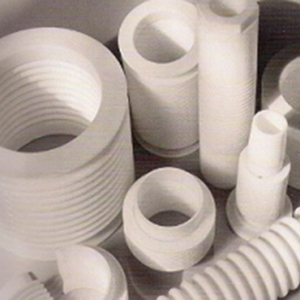

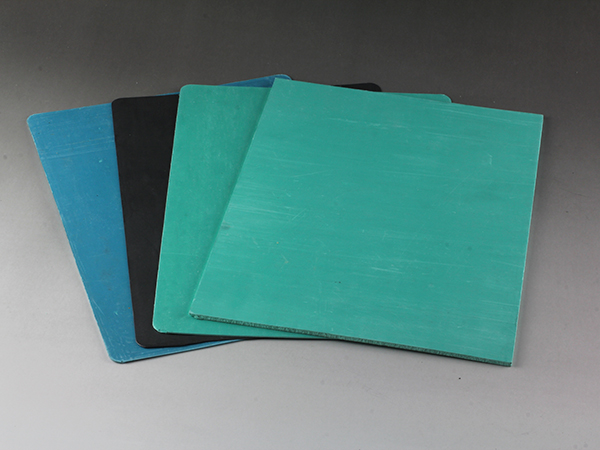

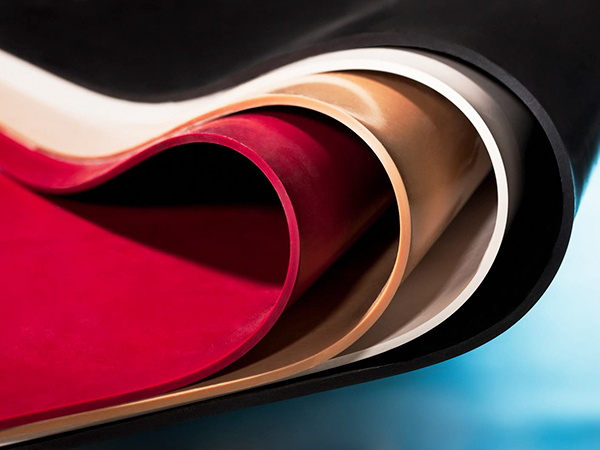

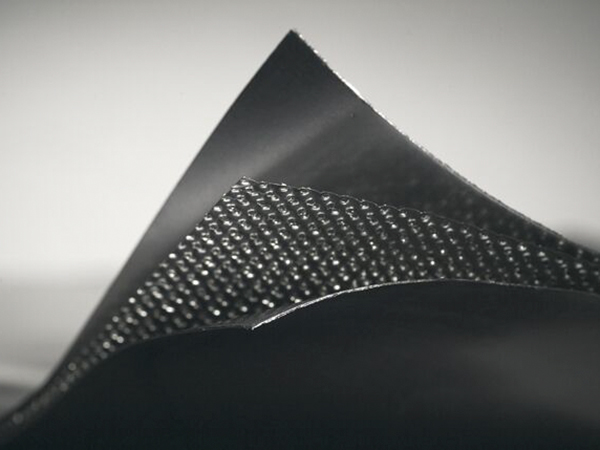

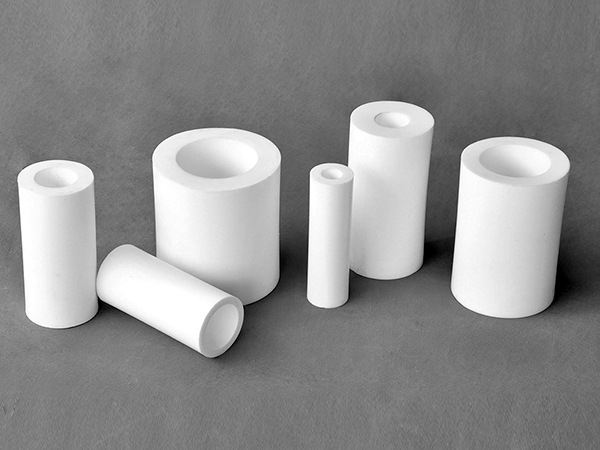

TOP SEALING manufactures a complete range of non-metallic gasket, Pure Graphite Gasket,Pure PTFE Gasket,Expanded PTFE Gasket,Non-asbestos Rubber and PTFE Envelope Gasket,EPDM PTFE Envelope Gasket,Non-Asbestos Rubber Gasket,Rubber Gasket,Envelope O RING,Ceramic Fiber Gasket. Non-metallic gaskets are manufactured from arimid fiber, glass fiber, elastomer, Teflon® (PTFE), graphite etc.. Non-metallic gaskets have excellent sealing, heat resistance and chemical resistance, used in Pipes, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, chillers, widely used in oil and gas, chemical processing, aerospace fields.

- Properties of Non-Metallic Gaskets Non-metallic gaskets can be made from a wide range of materials, each with their own unique properties. Some common materials used for non-metallic gaskets include: 1.Rubber - Rubber gaskets, typically made from elastomers such as neoprene, EPDM, or nitrile, are known for their flexibility, resilience, and ability to withstand high temperatures and pressure. 2.Graphite - Graphite gaskets are made from flexible graphite sheets and are known for their excellent thermal and chemical resistance, making them ideal for use in high-temperature and high-pressure applications. 3.PTFE - PTFE (Polytetrafluoroethylene) gaskets are made from a synthetic fluoropolymer and offer excellent chemical resistance and low friction, making them ideal for use in applications involving corrosive fluids.

- Applications of Non-Metallic Gaskets Non-metallic gaskets are used in a wide range of industrial applications, including: 1.Oil and Gas - Non-metallic gaskets are commonly used in the oil and gas industry for sealing pipes, valves, and other equipment that come into contact with fluids such as oil, gas, or water. 2.Chemical Processing - Non-metallic gaskets are used extensively in chemical processing plants for sealing pipes, tanks, and vessels that contain corrosive chemicals. 3.Aerospace - Non-metallic gaskets are used in aerospace applications to provide a seal between different components of aircraft engines, fuel systems, and hydraulic systems.

- Considerations for Selecting Non-Metallic Gaskets Selecting the right non-metallic gasket for a particular application requires careful consideration of several factors, including: 1.Chemical Resistance - It is important to choose a gasket material that is resistant to the specific chemicals that will be present in the application. 2.Temperature Range - Non-metallic gaskets have different temperature ranges, and it is important to choose a gasket that can withstand the temperatures that will be present in the application. 3.Pressure Rating - The pressure rating of a gasket is also an important consideration, as gaskets must be able to withstand the pressure of the fluids or gases they are sealing.

English

English русский

русский Español

Español