Aramid Fiber Gland Packing

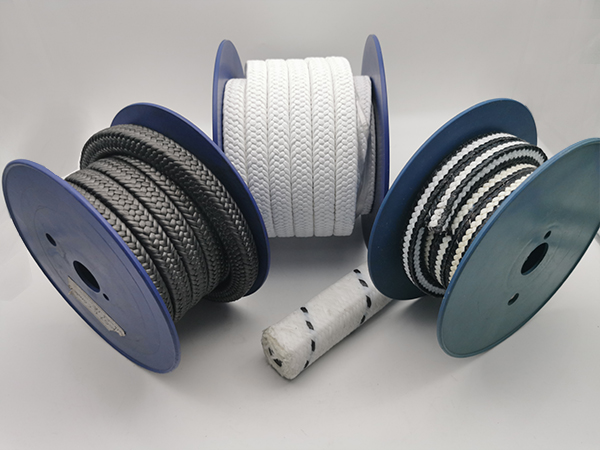

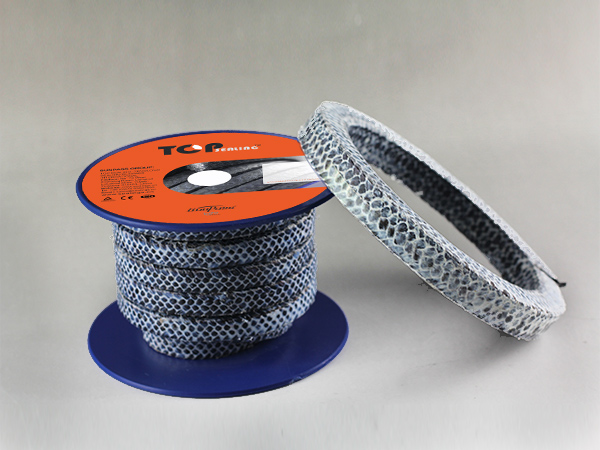

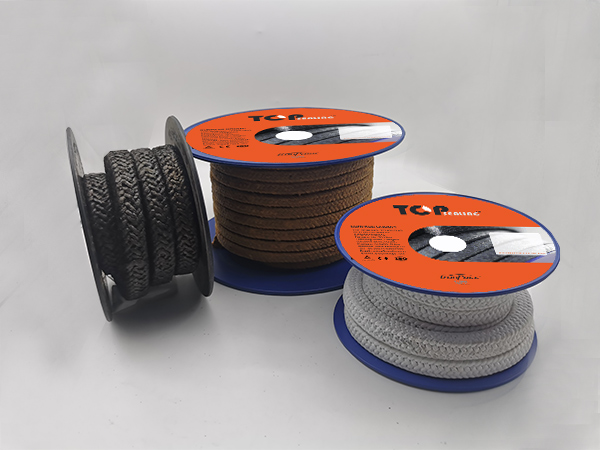

TOP SEALING manufactures a complete range of Aramid Fiber Gland Packing,Aramid Fiber Gland Packing, Silicon Core Aramid Fiber Gland Packing,Graphite PTFE and Aramid Fiber Corner Braided Gland Packing,Graphite PTFE and Aramid Fiber Zebra Braided Gland Packing,PTFE and Aramid Fiber Corner Braided Gland Packing,Aramid Wipping Pad,Fiberglass Core Aramid Packing.Aramid fiber yarn possesses outstanding properties of high strength, high modulus, high temperature resistance and flame resistance. Aramid packing has good wear resistance, chemical resistance, high resilience, and low cold flow, used in pumps, valves, and rotating machinery, widely used in chemical, petroleum, pharmaceutical, food and sugar, pulp, paper, and power industries.

- Advantages of Aramid Gland Packing: 1.High-Temperature Resistance: One of the key advantages of aramid gland packing is its exceptional thermal resistance. Aramid fibers are capable of withstanding temperatures of up to 600°C, making them ideal for use in high-temperature applications. They are widely used in industries such as chemical processing, power generation, and petrochemicals.

- 2.Low Friction and Wear: Aramid fibers are known for their low coefficient of friction, which reduces the wear and tear on the packing and shaft surfaces. This low friction also translates to reduced power consumption, making aramid gland packing a more energy-efficient option for industrial equipment. 3.Chemical Resistance: Aramid gland packing has excellent chemical resistance, making it suitable for use in environments with aggressive chemicals and corrosive fluids. They can resist a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons.

- Applications of Aramid Gland Packing: 1.Pumps and Compressors: Aramid gland packing is widely used in pumps and compressors for sealing rotating shafts. They provide excellent sealing and prevent leakage of fluids and gases, even under high pressure and temperature conditions. 2.Valves and Flanges: Aramid gland packing is also used in valves and flanges to prevent leakage and provide a tight seal. They can withstand high-pressure applications and offer exceptional chemical resistance, making them ideal for use in chemical processing plants and refineries. 3.Steam Applications: Aramid gland packing is commonly used in steam applications, where high temperatures and pressure are a concern. They provide reliable sealing and can withstand the harsh conditions of steam applications.

English

English русский

русский Español

Español