Manlid and Accessory

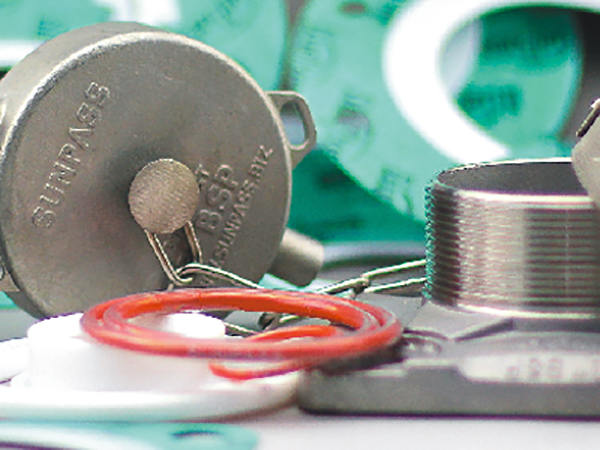

TOP SEALING manufactures a complete range of manlid, seals for manlid, manlid clamp, manlid lock pin for tank containers.These accessories have excellent sealing performance, high temperature resistance, chemical resistance, applied to manhole cover and manlid, widely used in ISO tank container, road tank and other tank container industry.

- 1.Importance of Manlid and Accessories for ISO Tank Containers: Manlid and accessories are important components of ISO tank containers, as they play a crucial role in maintaining the safety and integrity of the cargo during transportation. The manlid is a hinged cover located on the top of the tank container, which provides access to the interior of the tank for loading and unloading purposes. The manlid is equipped with various accessories, including a pressure relief valve, a gasket, and a locking mechanism, to ensure the safety and integrity of the cargo during transportation.

- 2.Applications of Manlid and Accessories for ISO Tank Containers: Manlid and accessories for ISO tank containers are used in various industries, including: Chemical Industry: ISO tank containers with manlid and accessories are commonly used to transport chemicals such as acids, alkalis, and solvents. The manlid and accessories ensure that the cargo remains safe and secure during transportation, protecting workers and the environment. Food Industry: Manlid and accessories for ISO tank containers are also used in the food industry to transport liquids such as fruit juices, vegetable oils, and wine. The manlid and accessories ensure that the cargo remains free from contamination during transportation. Pharmaceutical Industry: The pharmaceutical industry also uses ISO tank containers with manlid and accessories to transport liquids such as vaccines, drugs, and chemicals. The manlid and accessories ensure that the cargo remains safe and secure during transportation, protecting workers and the environment.

- 3.Advantages of Manlid and Accessories for ISO Tank Containers: Manlid and accessories for ISO tank containers offer several advantages, including: Safety: The manlid and accessories ensure that the cargo remains safe and secure during transportation, protecting workers and the environment. Convenience: The manlid and accessories provide easy access to the interior of the tank for loading and unloading purposes, making the transportation process more convenient. Versatility: Manlid and accessories for ISO tank containers can be customized to suit the specific requirements of different industries and applications, making them a versatile option for transportation.

English

English русский

русский Español

Español