|

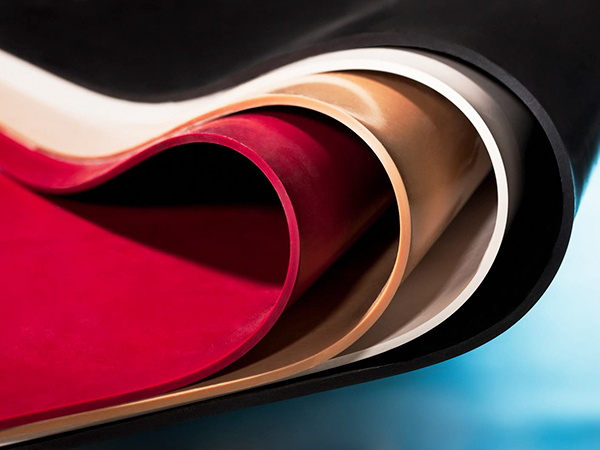

Filler Material

|

Temperature (℃)

|

Pressure (bar)

|

|

Graphite

|

-200~450(air) 650(reducing atmosphere)

|

300

|

|

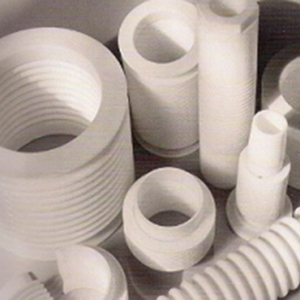

Expanded PTFE

|

-200-260

|

200

|

|

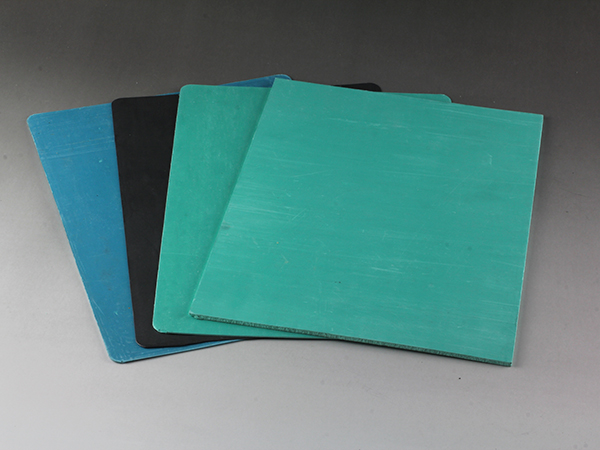

Non-Asbestos

|

-150-250

|

300

|

|

Mica/Graphite/Mica

|

-100-750

|

100

|

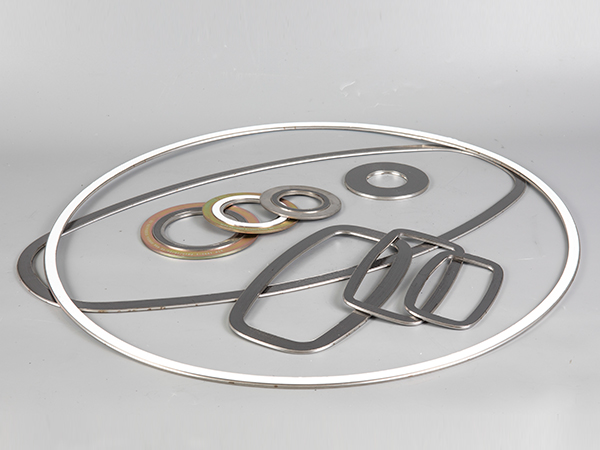

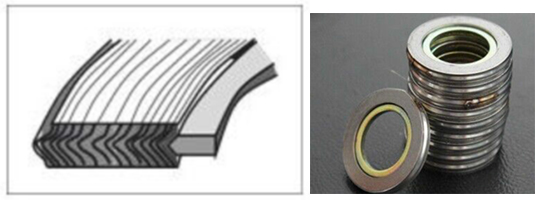

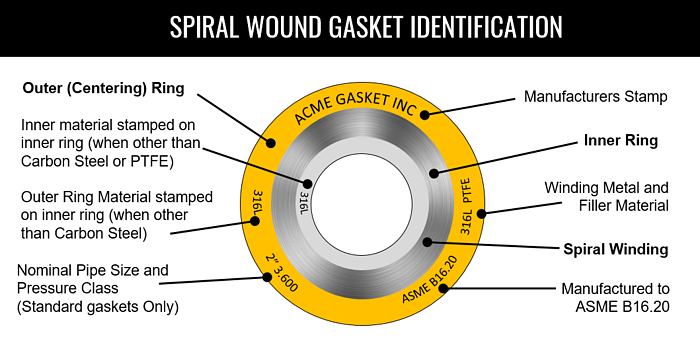

Types of Spiral Wound Gaskets:

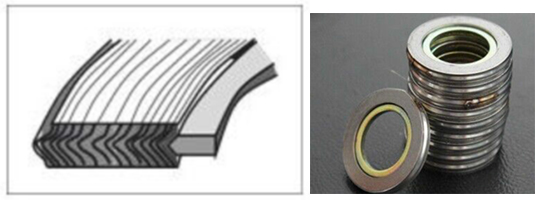

Basic Style Spiral Wound Gasket:

Basic construction style, inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies

Spiral Wound Gasket with Inner Ring:

Solid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimise erosion of flange faces. Suitable for male and female flanges.

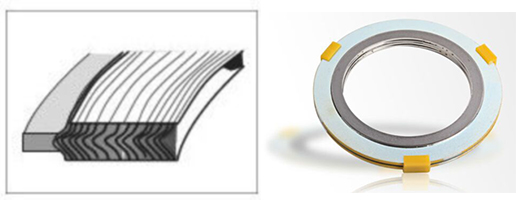

Spiral Wound Gasket with Outer Ring:

It’s an external ring which accurately center gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges, class 900 and above an internal ring is recommended

Spiral Wound Gasket with Inner & Outer Rings:

A style CG gasket fitted with internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion.Suitable for use with flat face flanges and specified for high pressure & temperature service, class 900 and above or where corrosive or toxic media are present. Other styles available upon request.

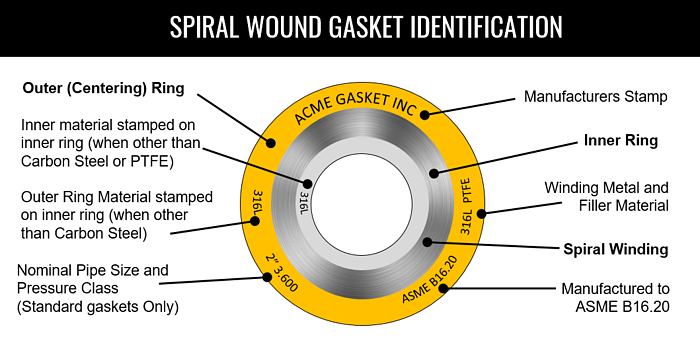

|

Ring & Strip Materials

|

|

|

Minimum

|

Maximum

|

|

Guide Ring

|

|

Material

|

F

|

C

|

F

|

C

|

Abbreviation

|

Color Code

|

|

SS304

|

-320

|

-195

|

1400

|

760

|

304

|

Yellow

|

|

SS316L

|

-150

|

-100

|

1400

|

760

|

316L

|

Green

|

|

SS347L

|

-150

|

-100

|

1400

|

760

|

317L

|

Maroon

|

|

SS321

|

-320

|

-195

|

1400

|

760

|

321

|

Turquoise

|

|

SS347

|

-320

|

-195

|

1700

|

925

|

347

|

Blue

|

|

Carbon Steel

|

-40

|

-40

|

1000

|

540

|

CRS

|

Silver

|

|

Alloy 20

|

-300

|

-185

|

1400

|

760

|

A-20

|

Black

|

|

Hastelloy B3

|

-300

|

-185

|

2000

|

1090

|

HAST B

|

Brown

|

|

Hastelloy C276

|

-300

|

-185

|

2000

|

1090

|

HAST C

|

Beige

|

|

Incoloy 800

|

-150

|

-100

|

1600

|

870

|

IN 800

|

White

|

|

Incoloy 825

|

-150

|

-100

|

1600

|

870

|

IN 825

|

White

|

|

Inconel 600

|

-150

|

-100

|

2000

|

1090

|

INC 600

|

Gold

|

|

Inconel 625

|

-150

|

-100

|

2000

|

1090

|

INCO 625

|

Gold

|

|

Inconel X750

|

-150

|

-100

|

2000

|

1090

|

INX

|

No Color

|

|

Monel 400

|

-200

|

-130

|

1500

|

820

|

MON

|

Orange

|

|

Nickel 200

|

-320

|

-195

|

1400

|

760

|

Nl

|

Red

|

|

Titanium

|

-320

|

-195

|

2000

|

1090

|

Tl

|

Purple

|

|

Filler Materials

|

|

|

Minimum

|

Maximum COT

|

|

Stripe

|

|

Material

|

F

|

C

|

F

|

C

|

Abbreviation

|

Color Code

|

|

Flexible

|

-350

|

-212

|

950

|

510

|

F.G.

|

Gray

|

|

Graphite

|

|

|

|

|

|

|

|

PTFE

|

-400

|

-240

|

500

|

260

|

PTFE

|

White

|

|

Ceramic

|

-350

|

-212

|

2000

|

1090

|

CER

|

Light Green

|

|

Mica Graphite

|

-350

|

-212

|

1100

|

590

|

MICA-GRA

|

Pink

|

English

English русский

русский Español

Español