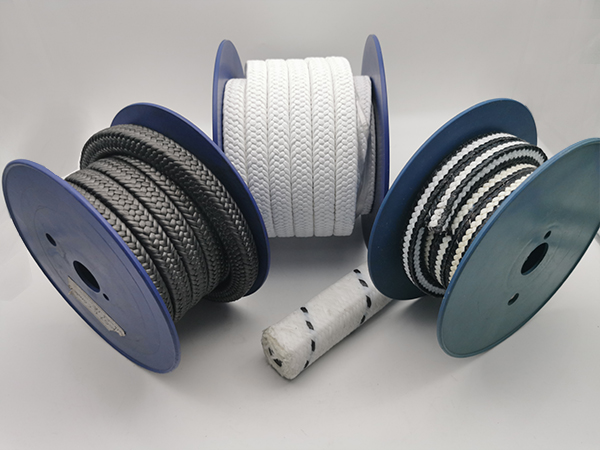

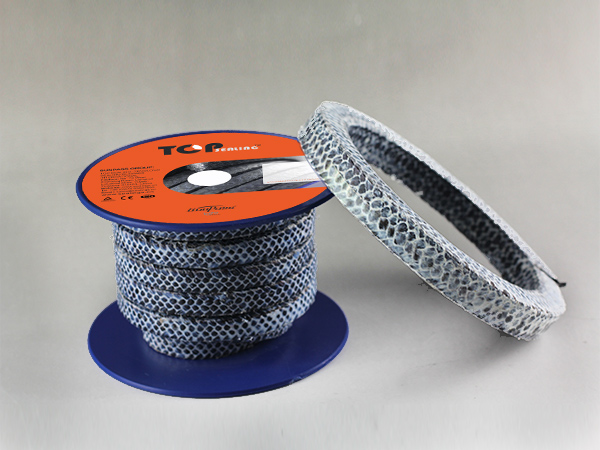

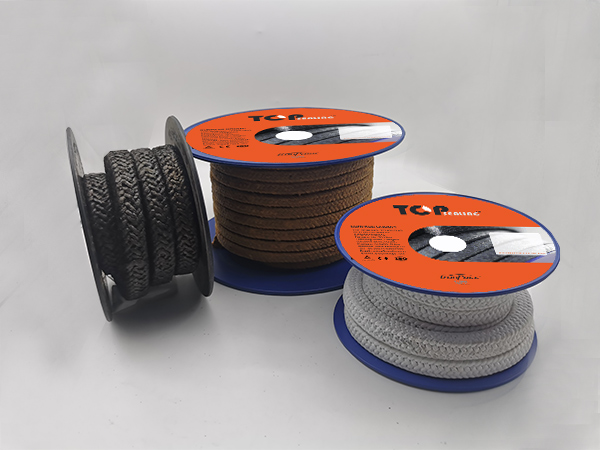

SUNPASS Injectable Packing unique properties assure superior performance and deliver major benefits resulting in improved plant and equipment maintenance at reduced cost. Its ability to fill any crevice makes it an effective seal on worn or grooved shaft sleeves.

It can form a cylindrical slider after the packing is closed by the packing rings at both ends in the packing culvert, which is the relative movement surface of the shaft. A very thin liquid film is produced between, and the frictional heat generated is close to zero due to the effect of the special material of the soft filler.

It requires no cooling of flush water. The operating costs of wasted water and product are eliminated. It will run leak free. Its low friction coefficient means equipment runs cooler, consumes less energy and last longer.

English

English русский

русский Español

Español