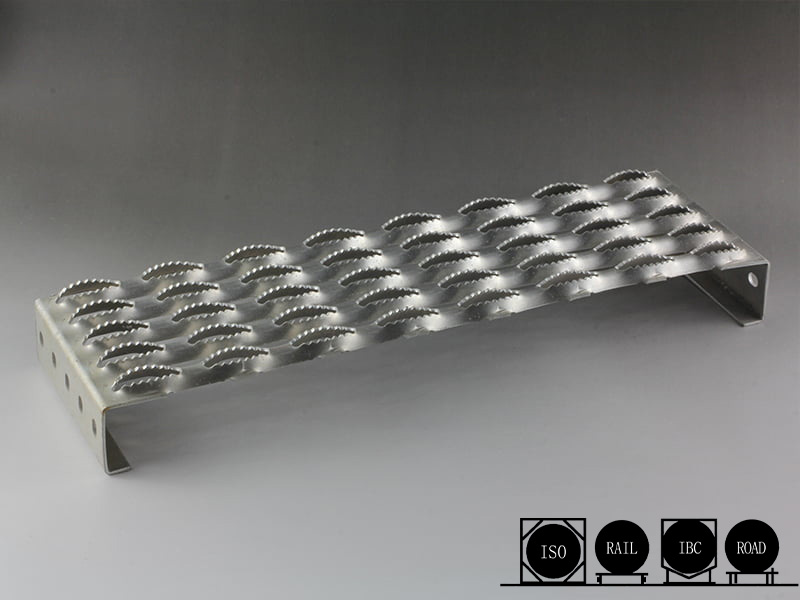

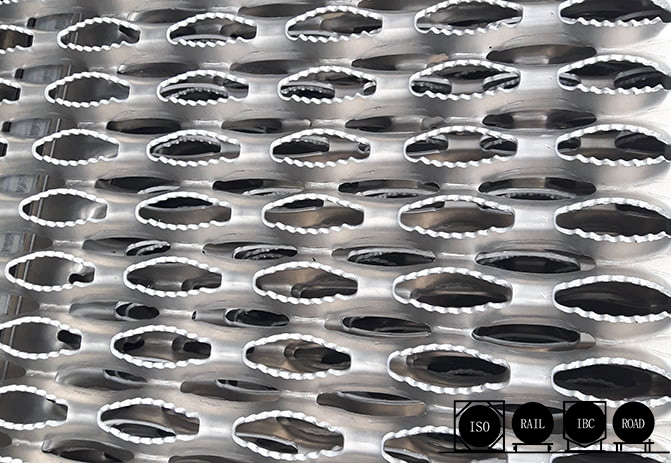

Aluminum walkways provide safe walking and working platforms for operators to inspect, maintain or operate the top equipment of ISO tank containers (such as manholes, valves, instruments, etc.). The surface is usually made of anti-skid patterns or coatings to prevent personnel from slipping in wet, oily environments.

Walkways are usually made of aluminum. Compared with steel walkways, aluminum materials greatly reduce their own weight (about 30%-50% lighter), reducing the overall transportation weight of tank containers. The tensile strength and fatigue resistance of aluminum fully meet the load-bearing requirements of frequent stepping (usually designed load ≥200kg/m²).

Aluminum walkways are naturally resistant to atmospheric, seawater and chemical corrosion, suitable for harsh environments such as sea transportation and chemical transportation, and can last for more than 10 years. Like steel, they need to be regularly rust-proofed to reduce long-term maintenance costs.

The size of the walkway matches the top structure of the tank container, which is easy to install and replace.

English

English русский

русский Español

Español